ZEROAVIA ADVANCES CERTIFICATION-INTENT FUEL CELL SYSTEM WITH FULL FLIGHT PROFILE GROUND TEST

KEMBLE, UK & EVERETT, WA – September 2, 2025 – ZeroAvia has completed a successful ground test of its certification-intent low temperature proton exchange membrane (LTPEM) fuel cell power generation system (PGS) for the ZA600 hydrogen-electric powertrain, marking a major step toward commercial certification.

The test simulated a 250-nautical-mile flight in a Cessna Caravan 208b – equivalent to the route between London Heathrow and Dublin Airport – and ran for 2 hours and 38 minutes. The fuel cell modules demonstrated stable performance, with each 200kW-capable unit producing 170kW for take-off, 132kW during a 23-minute climb, and 83kW in cruise for 90 minutes.

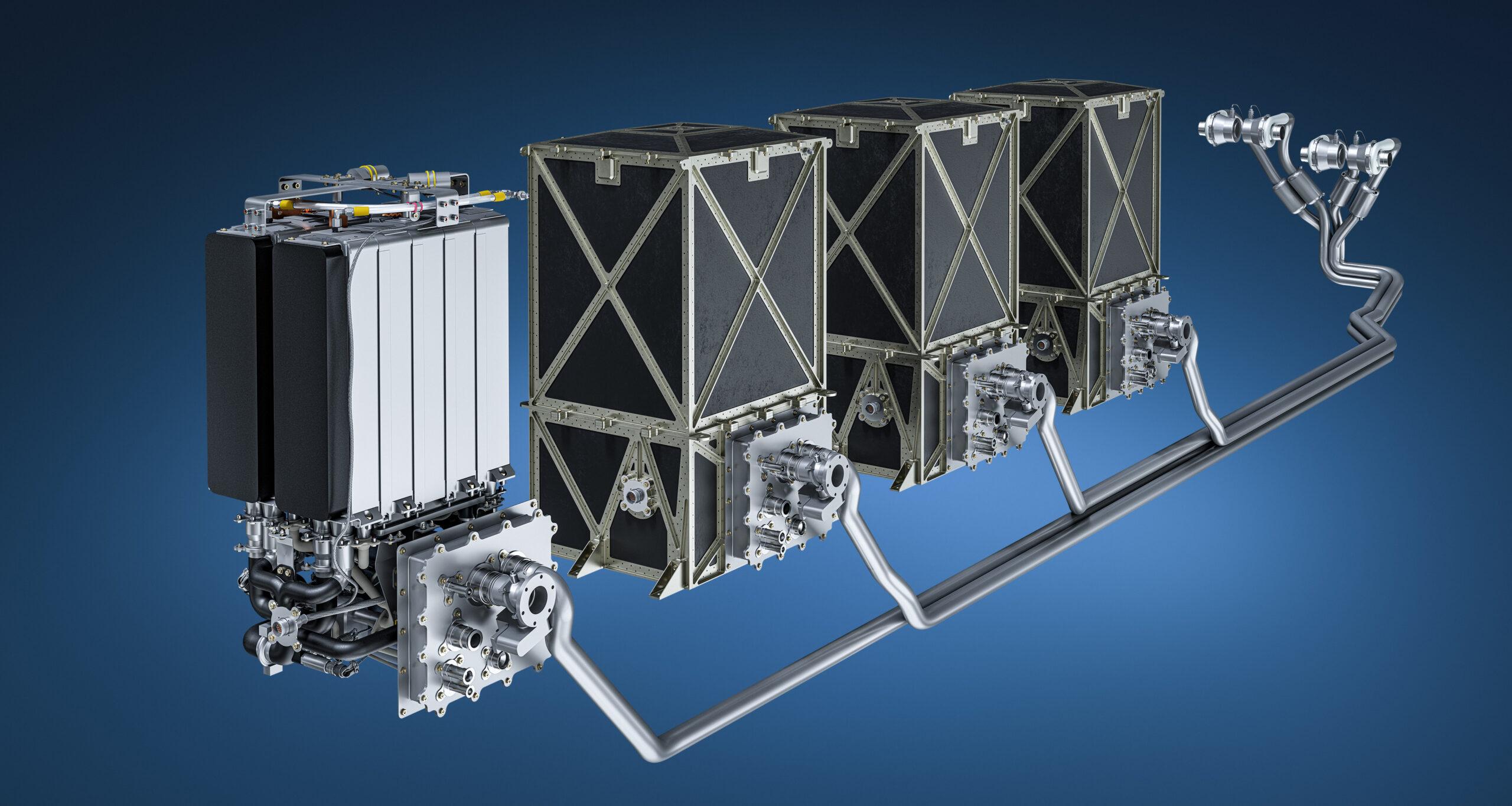

As part of the ZA600 hydrogen-electric system, four dual-stack modules will supply the company’s 600kW electric propulsion motor. Each module is capable of feeding DC power to four 200kW-rated inverters, which in turn deliver AC power to the motor segments. This architecture provides fault tolerance, enabling continued full-power operation even if one leg fails.

ZeroAvia has also introduced a bespoke Venturi ejector device, developed with The Lee Company, for hydrogen recirculation within the fuel cell. This passive system replaces the need for a heavy electrically driven blower, enhancing efficiency and power-to-weight ratio while simplifying certification pathways. Unlike complex hardware requiring DO254 qualification, the Venturi falls under DO160G environmental testing, easing approval.

The company’s ZA600 engine features a multi-stack balance-of-plant (BoP) architecture capable of 1.4 kW/kg power density. ZeroAvia’s investment in in-house testing facilities, including a 2MW-capable fuel cell test lab at its Gloucestershire R&D centre, has accelerated development and certification-readiness.

“We have shown the possibilities by flying a prototype of the ZA600 system on shorter missions, and we are now seeing the final design replicating customer needs in ground testing, and pushing the boundaries of performance with new innovations,” said Val Miftakhov, Founder and CEO of ZeroAvia. “What we have achieved with the Venturi is genuinely groundbreaking and further enhances an already commercially attractive, highly efficient and certifiable fuel cell propulsion system.”

ZeroAvia has already flown a prototype ZA600 aboard a Dornier 228 and is advancing ground tests for its larger ZA2000 system, designed for aircraft up to 80 seats including the ATR72 and Dash 8-400. The ZA600 is set to be the world’s first fuel cell module meeting CS-E and CS-23 certification requirements, with full engine ground testing of the final design planned in the coming weeks.

About ZeroAvia

ZeroAvia is pioneering hydrogen-electric propulsion systems for aviation, aiming to deliver lower emissions, reduced noise and operating costs, and greater energy independence. The company’s portfolio includes hydrogen-electric engines for up to 80-seat aircraft as well as propulsion technologies for eVTOL, rotorcraft and UAV applications.

SOURCE AND IMAGE: ZERO AVIA