There is a particular satisfaction in seeing a freshly serviced engine emerge from the hangar, ready to return to the skies. Behind that moment lies a precise routine of maintenance checks that ensure aircraft remain safe, efficient, and airworthy. For Etihad Airways’ Boeing 787 fleet at Zayed International Airport in Abu Dhabi, a recent collaboration with GE Aerospace has resulted in a dramatic 33% reduction in A-check time — a leap forward in operational efficiency.

Safety and Continuous Improvement

Airlines worldwide adhere to strict schedules of routine and non-routine maintenance, with checks tailored to aircraft type and engine model. Etihad’s 43-strong fleet of 787s is powered by GE Aerospace’s GEnx-1B engines, which undergo A-checks approximately every 500 cycles. These checks include GE Aerospace’s 360 Foam Wash and a borescope inspection (BSI), among other tasks.

GE Aerospace’s Customer Experience team partnered with Etihad to apply “kaizen” — the Japanese principle of continuous improvement — to these processes. By assembling cross-company teams directly on the maintenance floor, or genba, they were able to observe, map, and streamline the workflow.

Foam Wash Optimisation

The 360 Foam Wash process, a deep-cleaning method that improves engine compressor efficiency and fuel performance, originally took 12 hours to complete. A value stream map revealed that preparation and tool handling were major contributors to delays.

The team responded with a dedicated foam wash trolley, reorganised hose and cable storage, and upgraded the process for maintaining tablet connectivity throughout the job. These changes shaved four hours off the cycle, increasing efficiency by 33%.

Borescope Inspection Improvements

During the same A-check window, the GEnx-1B engines undergo a borescope inspection to capture internal images for condition assessment. Observations revealed that inspection times varied significantly with technician experience.

To address this, the team formed dedicated BSI teams, ensured experienced staff were on each shift, and upgraded borescope software to guide positioning and image capture. A new photo-tagging feature expedited reporting, while a pre-packed tool kit reduced preparation time. The result: a 33% gain in BSI process efficiency.

Replicable Success

The kaizen-led improvements have not only enhanced efficiency for Etihad Airways but also set a precedent for repeatable process optimisation across GE Aerospace’s global maintenance operations.

“These exercises delivered tangible, measurable results for our customer that can be replicated from engine to engine and airline to airline,” said project leader Hernandez.

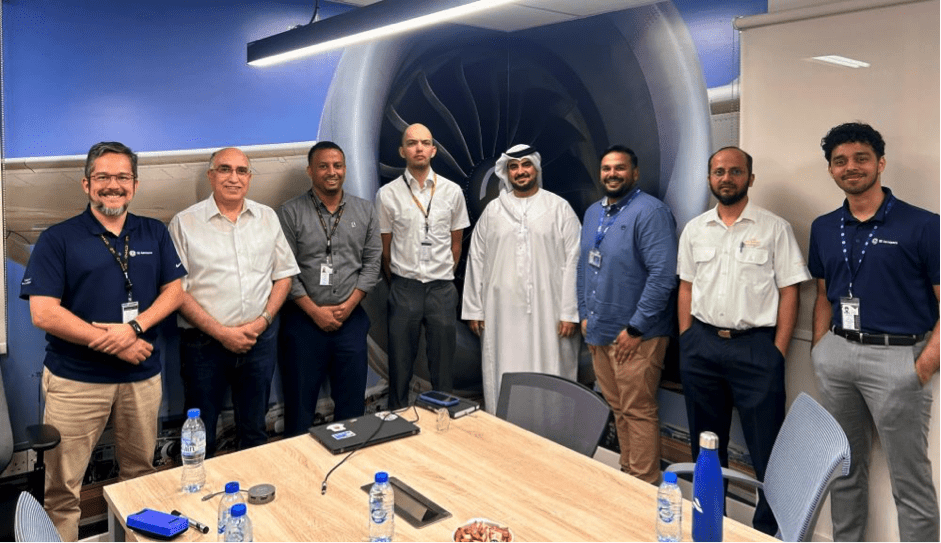

SOURCE AND IMAGE: GE AEROSPACE. CAPTION: The kaizen was facilitated by Francisco Hernandez (far left). Also participating in the kaizen along with representatives from Etihad Airways were GE Aerospace’s Bashar Doleh (second from left), Matthew Adams (fourth from left), and Adam Daud (far right).