Engine reliability remains central to Asia-Pacific airline growth, supporting schedule resilience, cost control and operational performance as regional fleets expand and demand continues to recover.

Airlines’ reputations are closely tied to how they serve customers and their ability to deliver safe, dependable operations. In the Asia-Pacific region, where post-pandemic air travel demand is recovering faster than anywhere else globally, this operational reliability is increasingly important.

If current growth trends continue, Asia-Pacific carriers could account for close to half of global air capacity by the end of the decade. However, this expansion is occurring alongside industry challenges, including supply chain constraints affecting OEM deliveries, pilot shortages and airport infrastructure limitations.

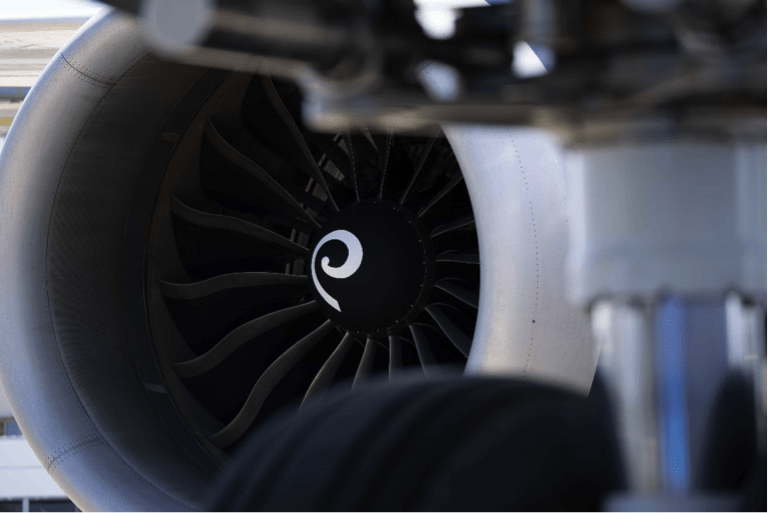

Aircraft reliability remains central to maintaining schedules and operational profitability, with propulsion system performance playing a particularly critical role. Airlines operating in Asia-Pacific require engines capable of delivering consistent performance, especially in hot, humid and dusty operating environments common across the region.

Supply chain disruptions have also required airlines to rely on existing fleets for longer than originally planned, further emphasising the need for durable and predictable engine performance.

Across the region, newer engines such as the GE Aerospace GEnx, used on the Boeing 787, and the CFM International LEAP, used on the latest generation Boeing 737 and Airbus A320 family aircraft, are delivering reliability trends that outperform the global average. At the same time, legacy engines such as the GE90, used on the Boeing 777, and the CFM56, used on current variants of the 737 and the A320ceo family, remain important to regional fleet operations.

Japan Airlines is among the prominent GEnx operators in Asia-Pacific, having operated GEnx-powered Boeing 787 aircraft since taking delivery of its first 787-8 in 2012. The airline highlights the engine’s contribution to daily operations, including high time on wing and predictable maintenance planning. As the airline’s 787 fleet expands, consistent engine performance combined with responsive technical support supports long-term operational reliability and efficiency.

GE Aerospace reported in October that the GEnx engine had surpassed five million flight hours with Japan Airlines, All Nippon Airways and Nippon Cargo Airlines combined. Across Japan, the engine powers 68 aircraft, with an additional 42 aircraft on order. Globally, the GEnx has accumulated more than 70 million flight hours since entering service in 2011, with more than 3,600 engines in service or on order. Approximately two-thirds of Boeing 787 aircraft are powered by the GEnx.

GE Aerospace supports Asia-Pacific operators through a regional service network that includes facilities in Singapore, Malaysia and South Korea, supporting engine availability, turnaround times and time-on-wing performance.

The aviation industry continues to manage supply chain and labour challenges that emerged during the Covid-19 period, including impacts on the MRO sector. Airlines in the region emphasise the importance of close collaboration with suppliers to manage these pressures.

Malaysia Aviation Group highlights long-term collaboration with GE Aerospace, dating back approximately 50 years to the introduction of CF6-powered McDonnell Douglas DC-10 aircraft. The relationship expanded with the introduction of Boeing 737 aircraft powered by CFM56 and CFM LEAP-1B engines.

Airline operators continue to stress that dependable engine performance supports both operational performance and cost predictability. As Asia-Pacific fleets expand and networks grow, engine reliability, maintainability and strong support infrastructure remain central to sustaining the region’s recovery and long-term growth trajectory.

SOURCE AND IMAGE: GE AEROSPACE