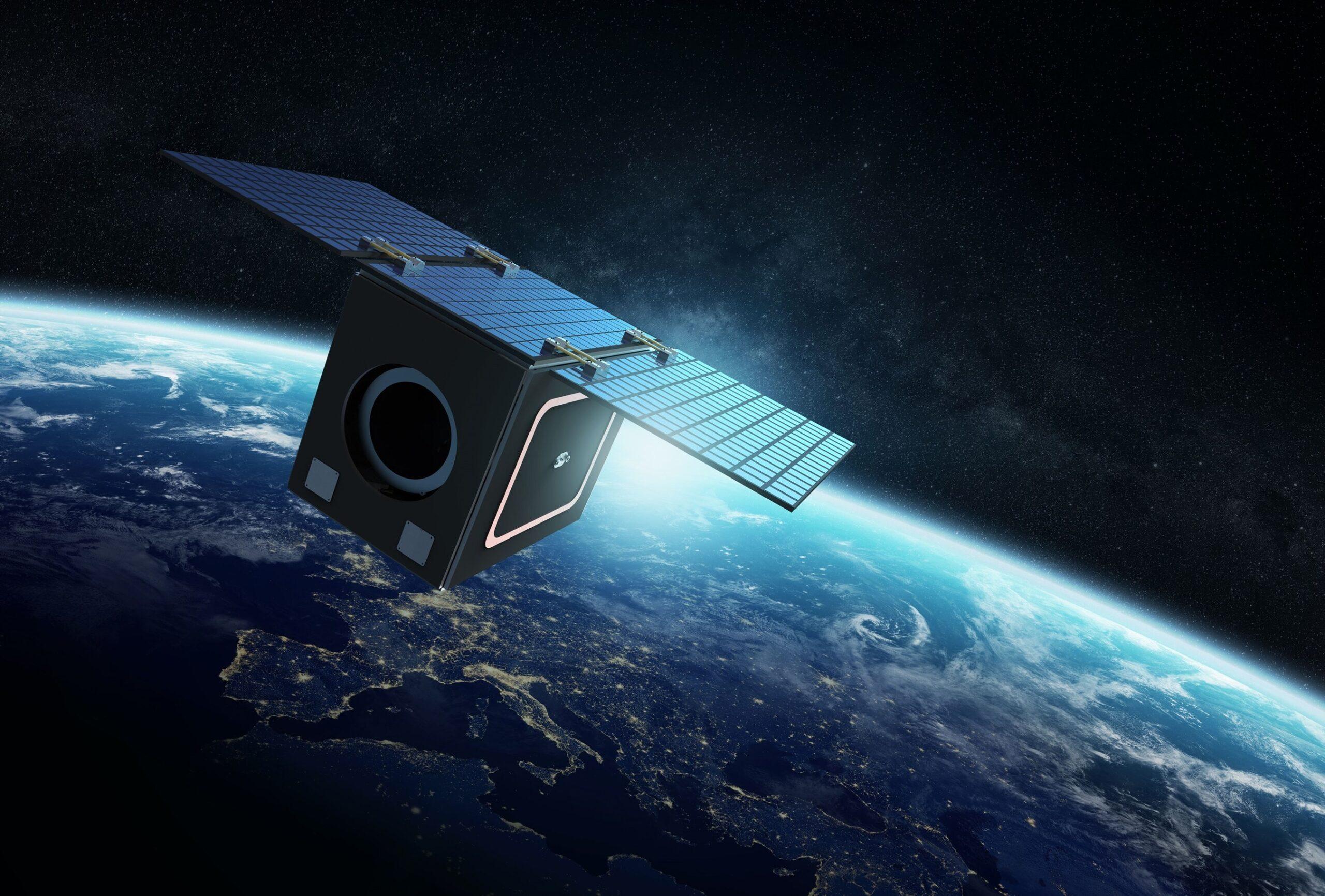

EL SEGUNDO, Calif., Sept. 10, 2025 – Boeing has introduced a new 3D-printed solar array substrate approach that compresses composite build times by up to six months on a typical solar array wing programme. The innovation cuts production cycles by as much as 50%, marking a major efficiency step in spacecraft manufacturing.

Flight-representative hardware has already completed engineering testing and is now moving through Boeing’s standard qualification path ahead of customer missions. The first 3D-printed solar arrays will fly with Spectrolab solar cells aboard small satellites built by Millennium Space Systems, both subsidiaries within Boeing’s Space Mission Systems organisation.

“Power sets the pace of a mission. We reached across our enterprise to introduce efficiencies and novel technologies to set a more rapid pace,” said Michelle Parker, vice president of Boeing Space Mission Systems. “By integrating Boeing’s additive manufacturing expertise with Spectrolab’s high-efficiency solar tech and Millennium’s high-rate production line, our team is turning production speed into a capability, helping customers field resilient constellations faster.”

The approach combines a printed, rigid substrate with modular solar technologies. By embedding features such as harness paths and attachment points directly into each panel, Boeing replaces dozens of separate parts and time-consuming tooling steps with one strong, precise component. This reduces complexity and enables a parallel build of the complete array.

Melissa Orme, vice president of Materials & Structures, Boeing Technology Innovation, added: “As we scale additive manufacturing across Boeing, we’re not just taking time and cost out, we’re putting performance in. By pairing qualified materials with a common digital thread and high-rate production, we can lighten structures, craft novel designs, and repeat success across programmes.”

Boeing has already incorporated more than 150,000 3D-printed parts across its portfolio, including over 1,000 radio-frequency parts on each Wideband Global SATCOM satellite currently in production. The company also deploys fully 3D-printed structures across multiple small-satellite product lines.

Looking ahead, the new solar array approach is designed to scale from small satellites to Boeing 702-class spacecraft, with market availability targeted for 2026. Robot-assisted assembly and automated inspection at Spectrolab are set to further improve consistency and reduce production time.

Boeing, a leading global aerospace company and the top U.S. exporter, continues to leverage innovation and advanced manufacturing to deliver solutions across commercial aviation, defence, and space systems, serving customers in more than 150 countries.

SOURCE AND IMAGE: BOEING